Since their introduction by JTM Products a decade ago, KOOLRite™ long life coolants have provided unparalleled performance, winning over many customers by maximizing machining performance along with operator comfort and safety. Today, we are proud to announce our latest breakthrough: SynMAX™ synthetic coolants. Ongoing research and development in improved additive chemistries has led to the invention of full synthetic metalworking fluids that outperform soluble oils and semi-synthetic on both steel and aluminum!

With SynMAX™ coolants you can:

Field trials of SynMAX™ Ultimate Coolants at select customers began in November of 2017. The promising results observed during these field trials provided us with the confidence we needed to recommend SynMAX™ Ultimate Coolants, knowing these products will exhibit the performance attributes you have come to expect from the KOOLRite™ Long Life Fluids.

The major difference between SynMAX™ coolants and traditional KOOLRite™ products is oil content. SynMAX™ fluids are 100% oil-free. They rely on breakthrough technology to provide lubrication to parts and tools. In addition, they provide more cooling with a higher water content.

SynMAX™ coolants are perfect for:

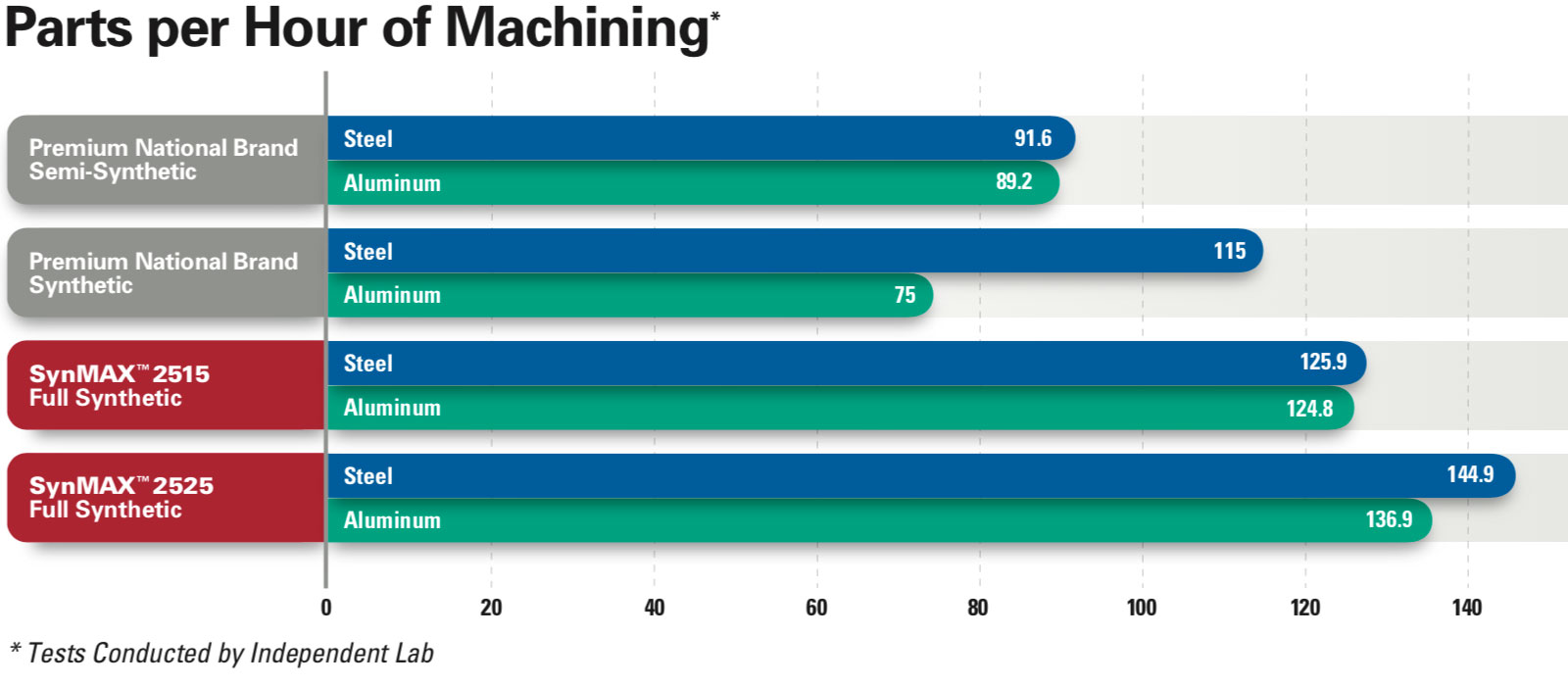

SynMAX™ products produce machining performance above and beyond that of traditional premium synthetics in addition to even premium semi-synthetics. Traditional synthetics lack machining performance because of their lack of oil. SynMAX™ has been carefully formulated to provide the best of machinability on not only aluminum but equally well on steel while remaining 100% oil-free.

| Features | Benefits |

|---|---|

| Enhanced lubrication | Provides increased tool-life contributing to cost savings and reduction of downtime Improves part finish contributing to cost savings by generating less scrapped material and less downstream processing |

| Improved cleanliness | Increases the usable life of the machine while decreasing downtime for cleaning and maintenance |

| Extended sump-life | Decreases fluid cost by reducing change-out, downtime, and waste generation Offers operator health and safety benefits by reducing exposure to harmful microorganisms and their released endotoxins |

Machine shops which:

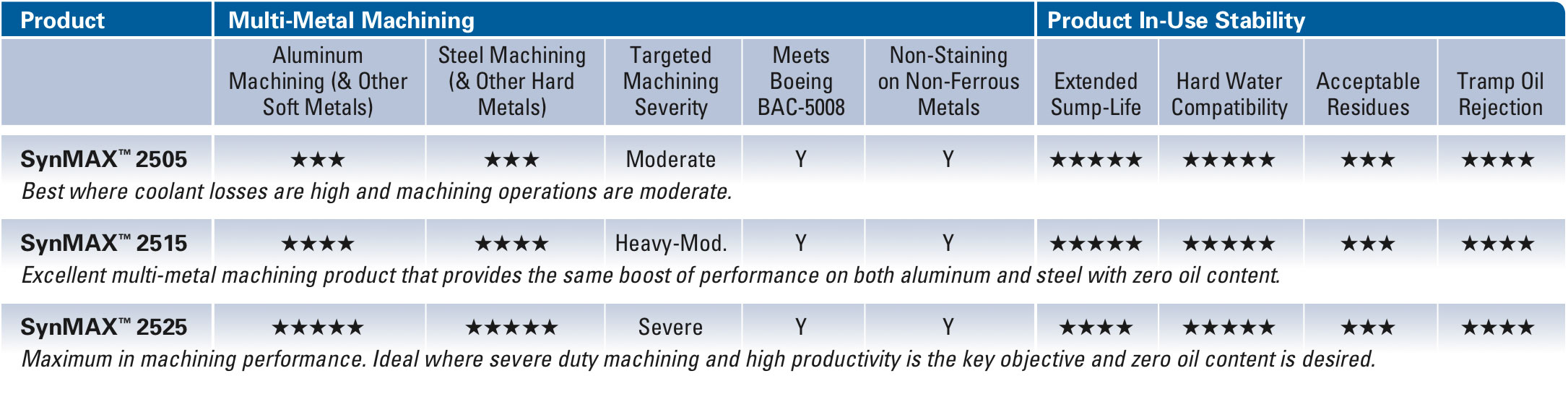

A selection chart can be found within the downloadable print-quality PDF available below.

|

ETNA Products 16824 Park Circle Drive, Chagrin Falls, Ohio 44023 Phone: 800-229-3862 / 440-543-9845 Fax: 440-543-1789 Copyright ©2025 ETNA Products, Inc. KOOLRite and SynMAX are trademarks of ETNA Products, Inc. |